Sloane is an accomplished rock climber, backpacker, cyclist, and skier. He has climbed rocks all over the world, including in Yosemite National Park and on Mount Kilimanjaro. He enjoys backpacking and cycling through beautiful landscapes, and skiing down challenging slopes.

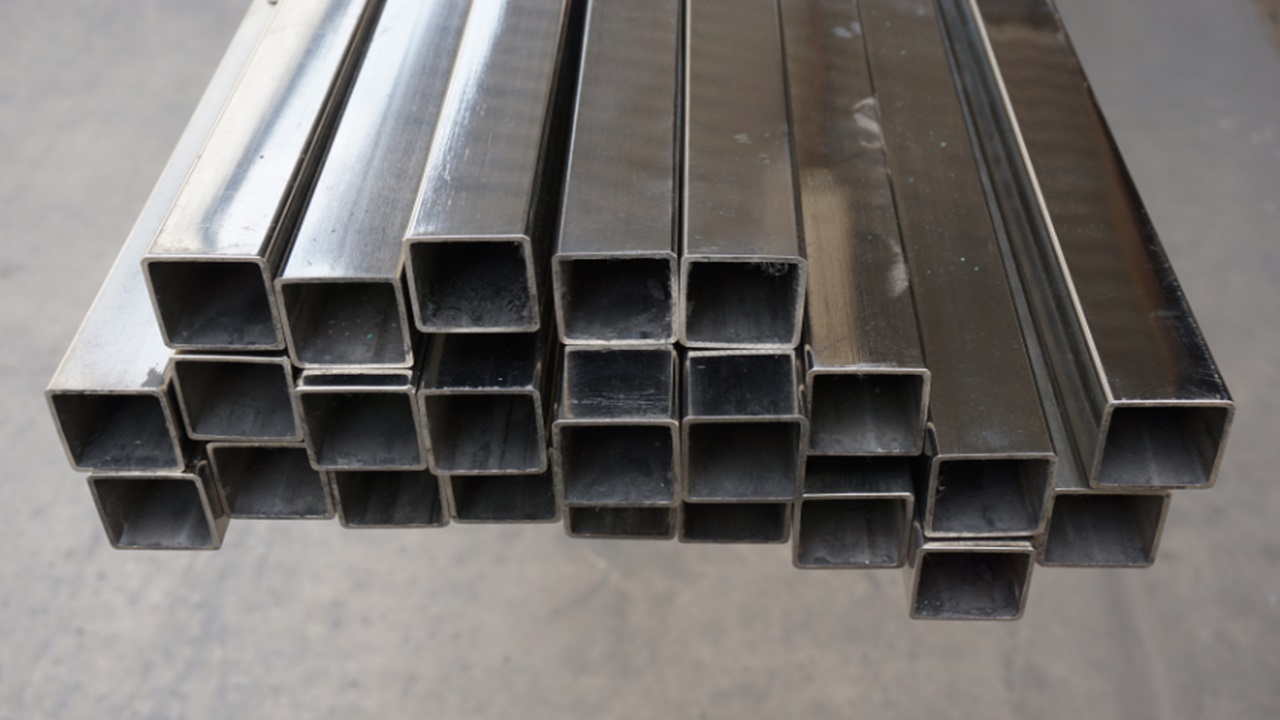

In the realm of modern construction, the seismic resilience of structures is a paramount concern, especially in regions prone to seismic activity. Architects and engineers are constantly in search of innovative solutions to bolster buildings’ earthquake resistance. A prominent contender in this endeavor is ASTM A500, a material that has proven to be a pillar of strength in creating seismic-resistant structures. Within this standard, the utilization of structural steel pipe further solidifies the material’s role in revolutionizing how buildings withstand seismic forces. Various websites are selling ASTM A500 pipes; you can visit a reliable and trustworthy website if you want to buy steel pipes for industrial or commercial projects.

ASTM A500: Defining Seismic Resilience

ASTM A500, a standard specification for cold-formed welded and seamless carbon steel structural tubing, stands out as a game-changer in the pursuit of seismic resilience. The inherent strength of ASTM A500 becomes particularly significant when considering its ability to absorb and dissipate seismic energy, playing a crucial role in preventing catastrophic failure during an earthquake.

Structural Steel Pipe: Building Resilience

A key component of ASTM A500, structural steel pipe, contributes significantly to the overall resilience of seismic-resistant structures. This specialized pipe provides a durable framework capable of flexing and bending without compromising the structural integrity of the building. Its ductility is a standout feature, allowing the material to deform and absorb energy before reaching a point of failure – a critical property in earthquake-prone regions.

Seamless Strength: The Welded Advantage

The seamless and welded nature of structural steel pipe manufactured from ASTM A500 enhances the material’s seismic performance. The uniformity of the steel pipe ensures consistent strength and reliability throughout the structure, minimizing weak points that could be vulnerable during an earthquake. This structural uniformity is pivotal in creating buildings that not only meet seismic design codes but surpass them in terms of safety and resilience.

Versatility Unleashed: Innovative Designs in Seismic Zones

Beyond its seismic-resistant properties, ASTM A500 provides engineers and architects with unparalleled flexibility in designing structures. The material’s versatility allows for the creation of aesthetically pleasing and functionally efficient buildings that can withstand the challenges posed by seismic events. This combination of innovative design and seismic resilience redefines the possibilities in earthquake-prone regions.

Durability And Longevity

In addition to its seismic-resistant properties, ASTM A500 is renowned for its durability and longevity. The corrosion-resistant nature of structural steel pipe ensures that the material can withstand the test of time, providing a reliable and low-maintenance solution for seismic-resistant structures. This long-lasting quality adds another dimension to the material’s appeal in the construction industry.

Conclusion

In conclusion, ASTM A500 has become a cornerstone in the construction of seismic-resistant structures. The use of structural steel pipe made from ASTM A500 is not just a choice; it’s a strategic decision to incorporate strength, ductility, and durability – essential elements in safeguarding buildings against the destructive forces of earthquakes. As the construction industry continues to prioritize safety and resilience, ASTM A500 stands as a testament to the commitment to innovation and the development of materials that set new standards in seismic-resistant structures.